Mayo Renewable Power is a Biomass Combined Heat & Power plant with a net electrical export of 42.4 MW. The plant uses virgin wood chip as the fuel for the boiler. The heat remaining after the electrical power generating process is used to provide heat to belt dryers, which are used for processing biofuels. The main plant items are a vibrating grate furnace, 125 Bar water tube boiler producing superheated steam at 540oC, a steam turbine, generator, condenser and 4 belt dryers.

Mayo Renewable Power is a Biomass Combined Heat & Power plant with a net electrical export of 42.4 MW. The plant uses virgin wood chip as the fuel for the boiler. The heat remaining after the electrical power generating process is used to provide heat to belt dryers, which are used for processing biofuels. The main plant items are a vibrating grate furnace, 125 Bar water tube boiler producing superheated steam at 540oC, a steam turbine, generator, condenser and 4 belt dryers.

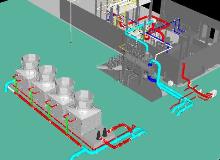

Fingleton White are responsible for the design of the Balance of Plant equipment for the process. The balance of plant is the equipment and systems that connects the 2 main plant items, that is the boiler and the turbine. The balance of plant is made up of, the high pressure steam piping, low pressure piping systems, condensate piping systems, feedwater piping systems, feedwater heaters, circulating water systems, instrument air system, belt dryers, cooling tower, circulating water pumps, combustion air heater, auxiliary cooling and process drains.

The development is on a brownfield site at the old Asahi site, Killala, Co. Mayo. The MRP project is currently under construction with operation scheduled for Q2 2017.